Swathing vs straight combining

Mustards are relatively resistant to pod shattering and straight combining is often the preferred harvest method. However, swathing may be beneficial in some situations depending on evenness, stage of maturity and crop height.

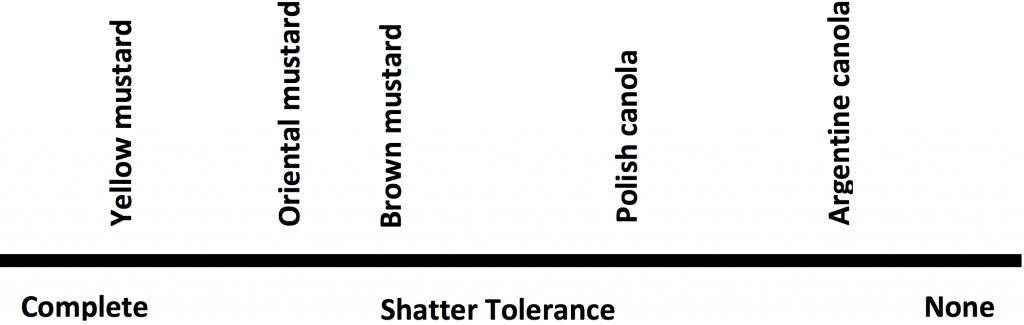

Shatter tolerance makes straight combining a viable option for mustards; with yellow mustard having the highest level of shatter tolerance and all mustards being more tolerant than canola (both Polish and Argentine canola). Shatter tolerance will allow the crop to be straight combined when plants are mature with little loss of seed during combining. For crops with low levels of shatter tolerance, swathing is the preferred harvest method. The shatter tolerance of different Brassica crops is illustrated below.

When deciding between straight combining and swathing, the evenness of the crop should be taken into consideration. Evenness of the crop refers to the range of relative maturity. In many fields, there will be a range of maturity with low-lying spots maturing earlier. For uneven crops, swathing can be used to force the fields to ripen consistently. If straight combining is used and harvest is delayed until all plants are the optimum level of maturity, the risk of pod shattering and harvest loss increases. If fields with a range of maturity are straight combined too early, green seed levels will increase which could result in downgrading and increased moisture content of the grain.

Stage of maturity should also be considered when deciding which harvest method to use. If the crop is overripe, straight combining will be preferred and will result in less shatter losses than swathing. Maturity should be monitored closely since hot dry conditions can cause the crop to mature and dry down quickly.

Time of swathing

Timing of swathing is very important and should begin when the majority of seeds are at less than 25 per cent moisture. At this time, seeds will feel firm when pressed between the thumb and forefinger. Some of the pods will have a purplish tinge; the lower pods will have started to change colour while the upper pods will remain green. It is important not to rely solely on pod colour change. Open the pods and look for seed colour change. For yellow and oriental mustard, swathing should occur when 75 per cent of the seeds have changed from green to yellow. For brown mustard, optimal swathing timing is when 60 per cent of seeds have changed from green to brownish or red.

During swathing, the mustard plants should be cut just below the lowest pods. This will provide stubble to anchor the windrow and prevent the swath from blowing. To ensure adequate anchoring, a swath roller should be used to compact the swath to minimize wind damage and loss. The roller should be set to ensure firm packing but care must be taken to avoid shattering of overripe pods due to over packing, which will also reduce drying.

The environmental conditions while the crop is in the swath will influence the number of green seeds. The moisture content should be above 20 per cent and the ambient temperature must be above 5˚C while colour change is occurring in order to reduce greed seed. Extreme high temperatures or frost shortly after swathing can destroy the enzymes required to remove green seed colour and will prevent colour change which could result in downgrading.

Straight combining

Straight cutting is beneficial when mustard is uniformly mature and has a low green seed content or if the crop is too short to properly anchor a swath. Harvest should occur when moisture levels are around nine per cent. When combining, set the reel speed at approximately the same speed as the ground speed to help prevent shattering. The header height should be just below the lowest pod to minimize the amount of stem or weed tissue processed through the combine. As mentioned for swathing, green seed content can be reduced in the crop as long as the seed moisture is above 20 per cent and the ambient temperature is higher than 5˚C. However, early fall frost while the crop is still green will kill the enzymes required for colour change, resulting in higher green seed content.

Desiccation

Desiccation is not commonly used for mustard. Application of a desiccant will provide accelerated plant dry down of green tissues in the canopy but will not hasten maturity. Desiccation offers the advantage of terminating any remaining green growth of pods and stems as well as drying down green weeds present in the field. Products containing diquat are registered for use in condiment mustard and application should occur at the same recommended for swathing, at approximately 75 per cent seed colour change.

Saflufenacil (Heat Brands/Detail) can also be used as a harvest aid. Application should occur when 65-80% of seeds have changed colour. Producers should always check with their grain buyer before applying any pesticides to their crop.

Pre-harvest weed control can be effective for controlling perennial weeds that are present late in the season and were not controlled with in-crop herbicide applications. RoundUp WeatherMax is the only herbicide registered for pre-harvest weed control in mustard. It is important to note that this product is not registered to be used as a desiccant and because of the different mode of action it will not result in accelerated plant dry down as seen with desiccants.

For complete and detailed information on desiccation timing, rates and pre-harvest intervals, refer to the registered product label recommendations and the Saskatchewan Agriculture Guide to Crop Protection.

Harvesting

Mustard should be combined when the moisture content has dropped to around nine per cent, when most seeds are mature and green seed content is low.

Depending on the condition of the crop, the cylinder speed should be between 400 and 800 rpm or at a speed where the number of cracked seeds is acceptable. Over-threshing at the cylinder or concave is a common problem that will result in cracked seeds, high dockage and loading the shoe with broken stems and pods. To keep the number of unthreshed and broken stems to a minimum, the concave clearance should be wider in the front, up to 25 mm (1 inch), and narrower, 3 to 13 mm (1/8 to 1/2 inch) at the back.

For mustard, the cleaning action depends more on shaking separation than wind separation. As a result, the fan speed should be set to approximately three-quarters the speed used for wheat. The air volume should just be adequate to move the material evenly across the sieves and the speed of the shaker should be increased by an additional 10 per cent (if possible).

The top sieve, or chaffer setting should be 6 mm to 10 mm (1/4 to 1/3 inch) and the lower sieve setting should be 3 to 6 mm (1/8 to 1/4 inch). The sieves should be adjusted to control the amount of trash in the hopper. If there is excessive trash, the sieves are open too much and if the sample is perfectly clean the sieves can be opened a bit.

< Previous: Pest Control: Diseases: Fungicides